EVM-2515T semi-automatic high-definition video measuring instrument (coaxial light)

Technical Parameters

|

Specification model: EVM-2515T

|

|

测量范围(mm)

|

外形尺寸(mm)

|

Host weight (Kg)

|

Maximum bearing weight (Kg)

|

|

X

|

Y

|

Z

|

L

|

W

|

H

|

|

250

|

150

|

150

|

1350

|

800

|

1520

|

170

|

20

|

|

Measurement Accuracy

|

|

Optical one-dimensional length measurement error: EU X/Y(1D)(μm)

|

2.0+L/200 MPE complies with JJF 1318-2011

|

|

Optical two-dimensional length measurement error: EU XY(2D)(μm)

|

2.5+L/200 MPE complies with JJF 1318-2011

|

|

Optical Z axis length measurement error: EU Z (μm)

|

3.5+L/200 MPE complies with JJF 1318-2011

|

|

Two-dimensional detection error: PF2D(μm)

|

2.0 MPE complies with JJF 1318-2011

|

|

Image probe detection error: PFV2D(μm)

|

2.0 MPE complies with JJF 1318-2011

|

|

Serial number

|

Name

|

Specification and description

|

|

1

|

Host and machine

|

The main body of the fuselage is made of high-precision natural granite, which has stable temperature characteristics and resistance to aging deformation.

|

|

2

|

Control System

|

USB network board to ensure the stability and safety of the machine

|

|

3

|

Easson measurement software system

|

Automatic version of optical vision measurement software

|

|

4

|

Camera

|

1.3 million digital high-definition web camera

|

|

5

|

Grating ruler

|

0.01μm absolute grating

|

|

6

|

Guide

|

The three axes adopt precision ball screw guides, the speed is greatly improved, and the operation is stable

|

|

7

|

Motor

|

DC servo motor

|

|

8

|

Lens

|

Easson independently designed TC precision manual zoom manual zoom telecentric lens (standard coaxial light) actual magnification: 30-145×

|

|

9

|

Lighting system

|

5 rings and 8 zones LED cold light source is independently controlled for each segment, 256 levels of brightness adjustable

|

|

10

|

Brand Computer

|

WIN7/WIN10

|

|

23.8 HD

|

|

11

|

Operation method

|

232 control box, mouse hauling, keyboard control

|

|

12

|

Probe

|

Renishaw MCP probe (including one Φ1 and one Φ2 stylus)

|

Environmental conditions and requirements

|

The temperature requirements of the imager room:

|

|

Room temperature (temperature control room)

|

18~22°C

|

|

Temperature gradient (time)

|

1°C /h

|

|

Temperature gradient (time)

|

2°C /24h

|

|

Temperature gradient (space)

|

1°C /m

|

|

Humidity requirements for imaging room:

|

|

relative humidity

|

40-70%

|

|

Power requirements:

|

|

Voltage

|

220V ± 10%

|

|

frequency

|

50/60 Hz

|

|

shock

|

Below 15Hz<0.001g

|

|

power consumption

|

1000VA

|

|

Electrical equipment requires reliable grounding: the grounding resistance is less than 4 ohms

|

3. Probe measurement:

1. Working principle of stylus:

The stylus is an integral part of the measurement system. When the stylus head of the stylus contacts the workpiece, the change of the stylus head drives the probe mechanism to generate signals, and the measurement results are obtained after processing to achieve the purpose of detection.

2. Source of stylus measurement error

Ambient temperature and humidity, the stiffness of the stylus component material, the accuracy of the stylus head, the coaxiality of the stylus head and the stylus shank thread, the accuracy of the stylus shank thread, and the contact position of the stylus head and the workpiece.

It is recommended that the stylus should be calibrated during precision measurement, otherwise the measurement accuracy will be reduced.

3. The principle of stylus selection

3.1. The diameter of the measuring ball should be as large as possible to reduce the influence of the surface roughness of the tested workpiece on the detection result.

3.2. The stylus should be as short as possible. If the stylus is too short, the less bending or deformation, the higher the accuracy.

3.3. Minimize the joints. Each additional connection point increases a potential bending and deformation point.

3.4. Stylus connection form: threaded or straight shank connection

3.5. The basic mechanism of the spherical thread connecting the straight stylus: stylus head, stylus rod, stylus handle, extension rod, anti-collision protection seat, etc.

Probe measurement contains 2 menus, namely "probe measurement" and "3D auxiliary measurement".

The "probe measurement" menu is mainly used to perform a single measurement of an object, and contains the following commands:

Probe settings: Carry out some general settings of the probe, including probe calibration.

Horizontal line measurement: used to measure a straight line parallel to the horizontal plane.

Horizontal circle measurement: used to measure a circle parallel to the horizontal plane.

Spatial point measurement: used to measure any point in space, this command must set the datum plane.

Space line measurement: used to measure any straight line in space, this command must set the datum plane.

Space circle measurement: used to measure any circle in space, this command must set the datum plane.

Solution setting: It is used to set the compensation method of spatial points, lines and circles, such as whether to project to the reference plane and so on.

Height measurement: used to measure the distance of an object in the Z direction.

Plane measurement: Use a probe to take at least 3 points to fit a plane to obtain this

The flatness of the plane and other parameters.

Ball measurement: Use a probe to take at least 4 points to fit a sphere to obtain parameters such as the diameter of the sphere.

Cylinder measurement: Use the probe to take 6 points to fit a cylinder. This command must set the datum plane.

Cone measurement: Use the probe to take 6 points to fit a cone. This command must set the datum plane.

Behavioral tolerance measurement: flatness, parallelism, perpendicularity, inclination.

Remarks: The probe has automatic rebound protection and anti-collision function. The collision speed and rebound distance can be set according to the measurement requirements. The Yixin probe automatic measurement system can ensure the smoothness of the contact between the probe and the workpiece surface and ensure the stability and continuity of the measurement force, thereby improving the repeatability of the product. The automatic rebound function of the Z-axis probe can prevent strong impacts. , Improve the durability and reliability of the product.

3. Software features

Introduction to the main functions of the smart measurement software Easson2D

1. Basic functions:

●Cartesian coordinate/polar coordinate conversion ●Absolute/relative/working coordinate conversion

●Metric/English conversion ●Degree/degree, minute, second conversion

●Point/Point Group ●Two-point/multi-point seeking line

●Three-point/multi-point finding circle and arc ●B-spline line

●The distance between two points ●The average distance between two lines

●The distance between dots and lines ●The distance between two circles

●Circular line distance ●The angle and intersection between two lines

2. Special functions

1. The software controls the light source. The upper light source is a four-phase lamp, and the lower light source is a straight light source, which increases the adaptability of the machine.

2. There is no need to adjust the position for measuring the workpiece, and the software provides coordinate translation, rotation, and position.

3. Mark/move the size directly in the image and geometric area. Straight line trimming and extension function.

4. Geometry zone points, lines, circles/arcs and straight line endpoints, midpoints, circle centers and quadrant points are automatically captured.

5. Adjust the CCD parameter settings to improve the self-adaptive force; remove the burr function to obtain the measurement data correctly.

6. Use the image tool to quickly and automatically grab the boundary points of the basic geometric contours, and directly fit the lines, circles, and arcs.

7. The workpiece in the measurement area is zoomed in and outputted by the camera and converted into (.bmp, .jpg).

8. Measurement data output, converted into WORD (.doc), EXCEL (.xls).

9. SPC function, directly output control chart, process capability index, and convert it into WORD, EXCEL

10. Direct output of mechanical graphics in .dxf format to realize 2D reading function and seamless connection with AutoCAD and other software.

11. Can be transferred to .DXF format files, and compared with the actual workpiece or measurement graphics. And you can directly pick two points in the image area to get the error measurement value.

12. Provide in-plane straightness, roundness, and angle analysis for effective quality inspection

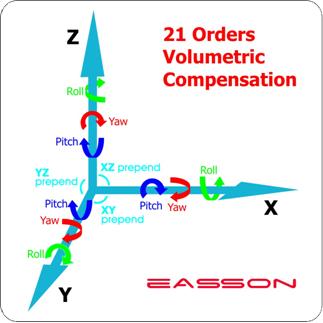

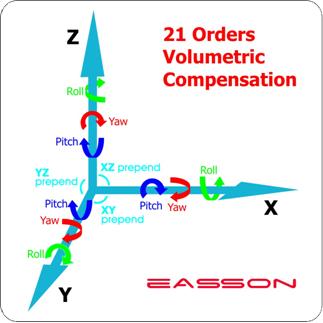

13. The accuracy of the machine is compensated to improve the measurement accuracy.

14. The software can measure multi-deformation, groove shape, arc chamfering and virtual measurement.

15. The 2.5D measurement software can be upgraded, with functions: slope, height, sphere, cylindrical measurement, etc.

16. Re-measurement function: This function can re-change the measurement method, lighting, magnification, etc., for the elements that have been measured, and then refresh the measurement data, and the related element data will also be refreshed (such as: two-line construction distance, if If one of the lines is re-measured, the distance element data will also be refreshed).

17. Modify, edit and view edge seeking status: The software can modify and edit the edge seeking range, light source brightness, magnification, etc. of any measurement element. You can also view the edge-finding status of a certain element measured before (including the position of the edge-finding, the brightness of the light source used, the magnification and the original point taken, etc.), so that the user can control the status of the whole process of measurement.

4. Machine characteristics

The main body of the fuselage is made of high-precision natural granite, which has stable temperature characteristics and anti-aging deformation ability to ensure the stability of measurement and the accuracy of long-term use.

All Yixin's optical image measuring instruments are equipped with the F-1 high-precision full-closed-loop automatic zoom optical lens developed by our company as standard, with high performance and ultra-low distortion to ensure the accuracy of measurement.

High-precision fully closed loop automatic zoom optical lens

The principle of telecentric optics: adopting the optical design of parallel light path, the size of the object image will not change with the distance from the lens, causing the effect of perspective to produce additional measurement errors.

Automatic zoom optical telecentric lens (Telecentric), professionally manufactured by Yixin, is a lens specially designed to correct the parallax of traditional lenses. It can be within a certain object distance range, so that the image magnification will not vary with the object. The distance varies, which is a very important application when the measured object is not on the same surface.

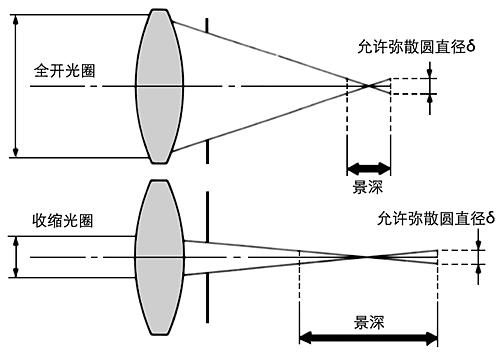

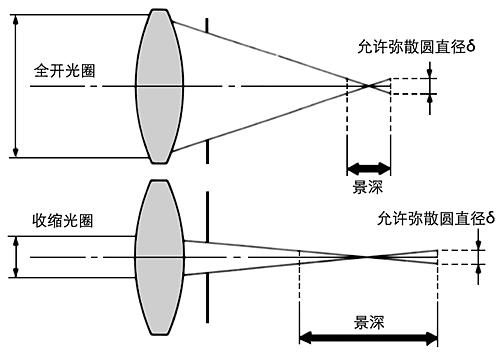

The aperture is a device used to control the amount of light passing through the lens and entering the photosensitive surface of the body. Specifically, if the brightness is high, it can shrink to reduce the total amount of light passing through; on the contrary, if the light is very weak, it can be Make it larger to allow more light to enter. The larger the aperture, the smaller the depth of field; the smaller the aperture, the greater the depth of field. The farther the working distance, the greater the depth of field; the closer the working distance, the smaller the depth of field

At present, all the automatic machine EVM series have to do 2000 times of "burn-in measurement" before leaving the factory. We use a glass ruler to move the table in the four directions, X, 45 degrees, Y and 135 degrees. Repeat the direction measurement 500 times, a total of 2000 times, measuring a length of 180 mm, we will record all the measured data, the maximum and minimum size difference must be guaranteed to be within 2um before leaving the factory!

F1 High-precision, fully closed-loop, automatic zoom telecentric lens The features are as follows:

Adopt the high-precision, high-resolution ring-type grating ruler specially developed and designed by our company for F-1 for full closed-loop position feedback

High resolution, fully closed loop position feedback, avoiding the repetition error of image multiples caused by gear transmission gap, greatly improving the repeatability of the whole machine measurement.

The resolution of the ring grating is 20 times higher than that of the previous generation zoom lens.

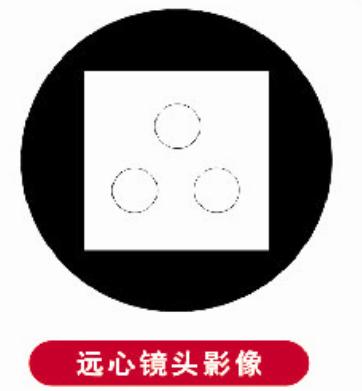

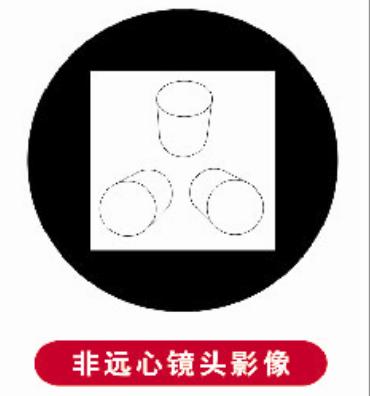

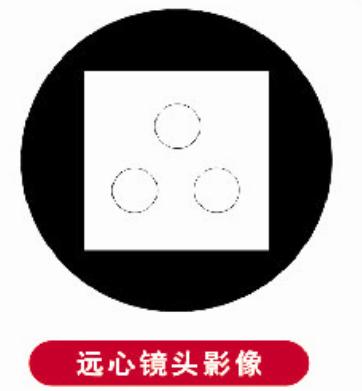

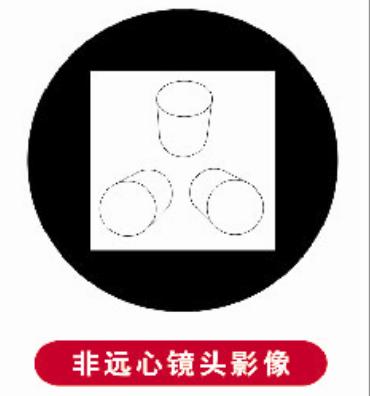

Yixin telecentric lens VS non-telecentric lens

The use of non-telecentric lenses for imaging will produce perspective artifacts and bring test errors.

Use a telecentric lens to correct the image of the light source without distortion and improve the measurement accuracy.

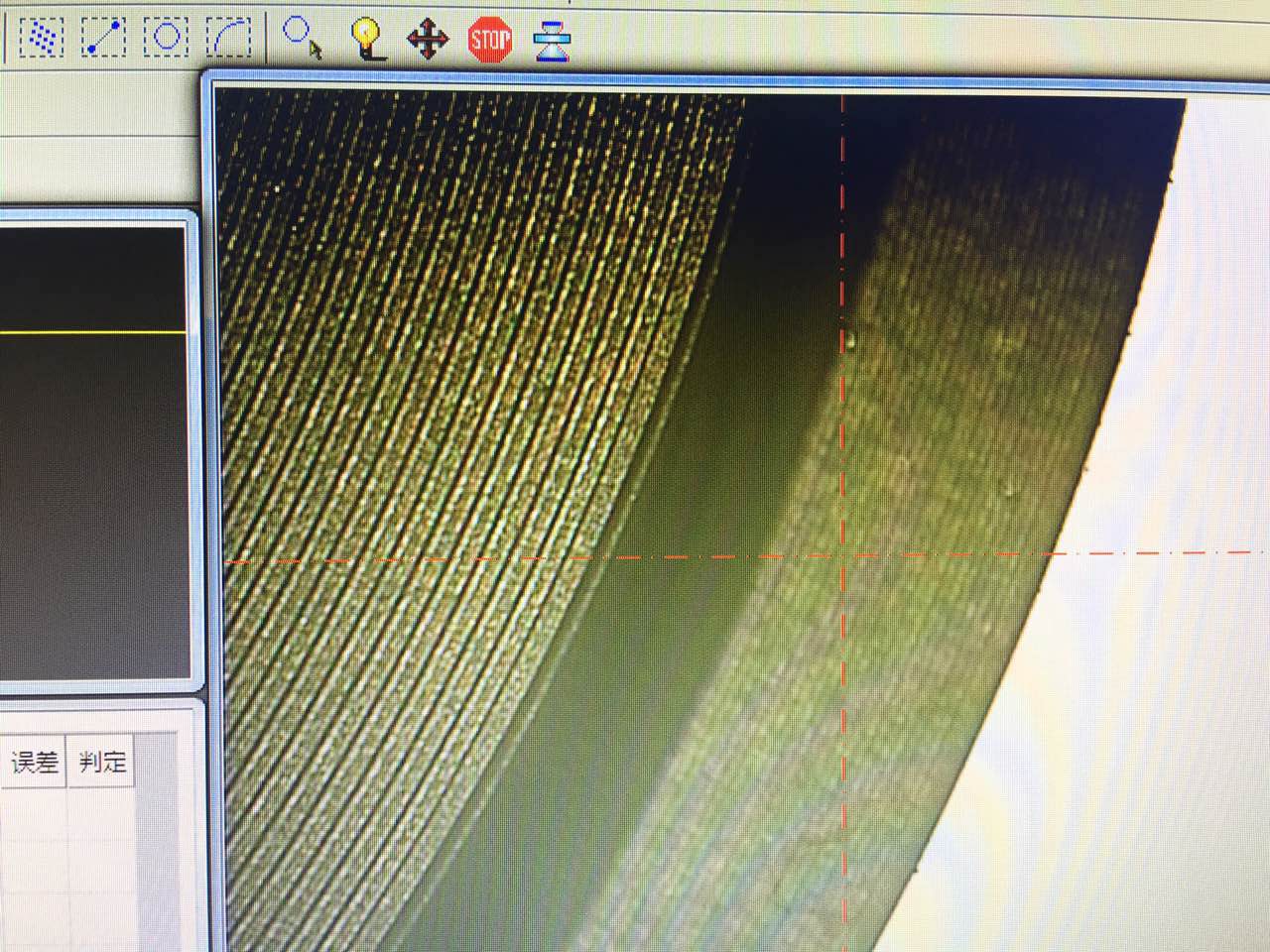

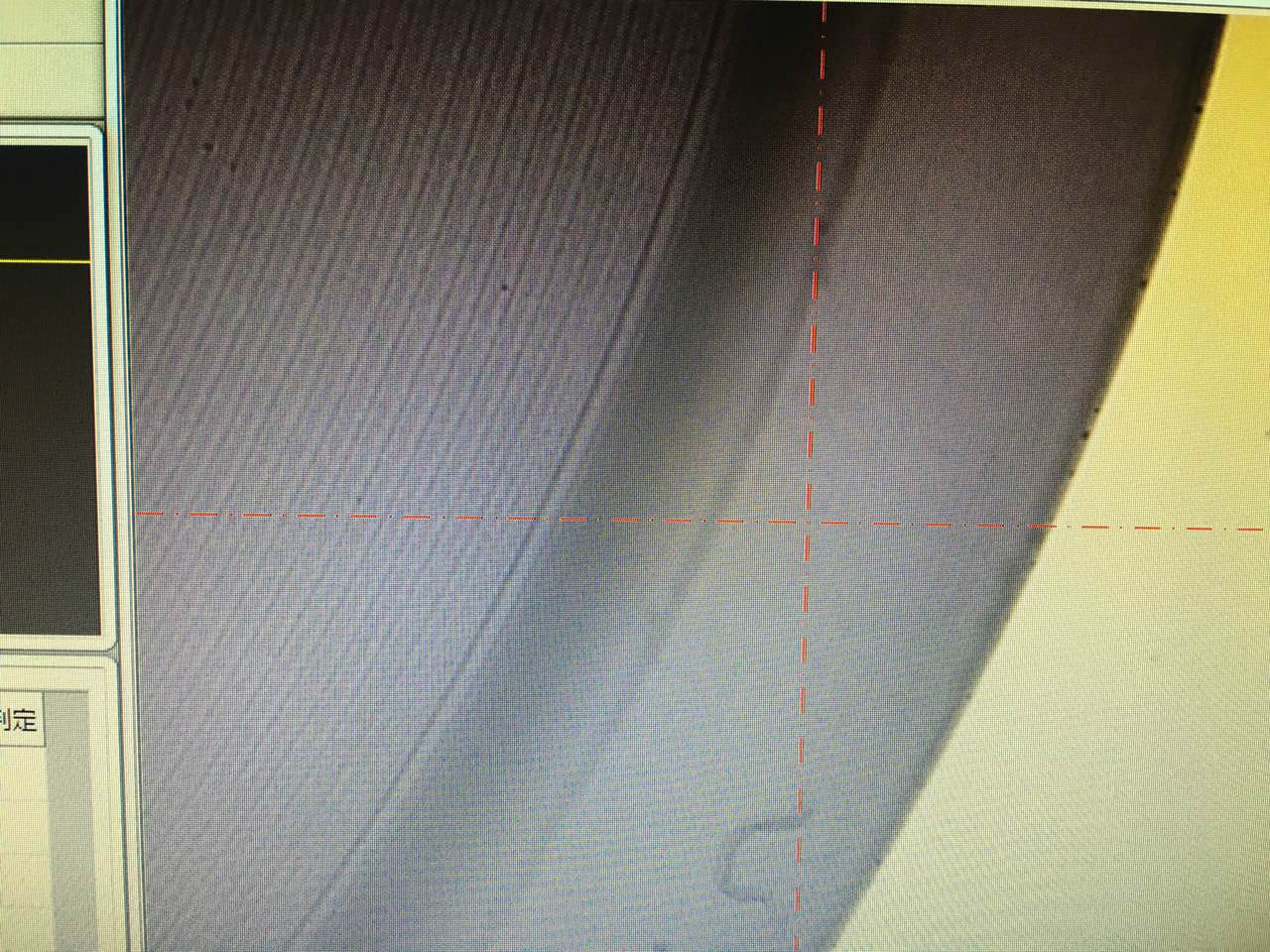

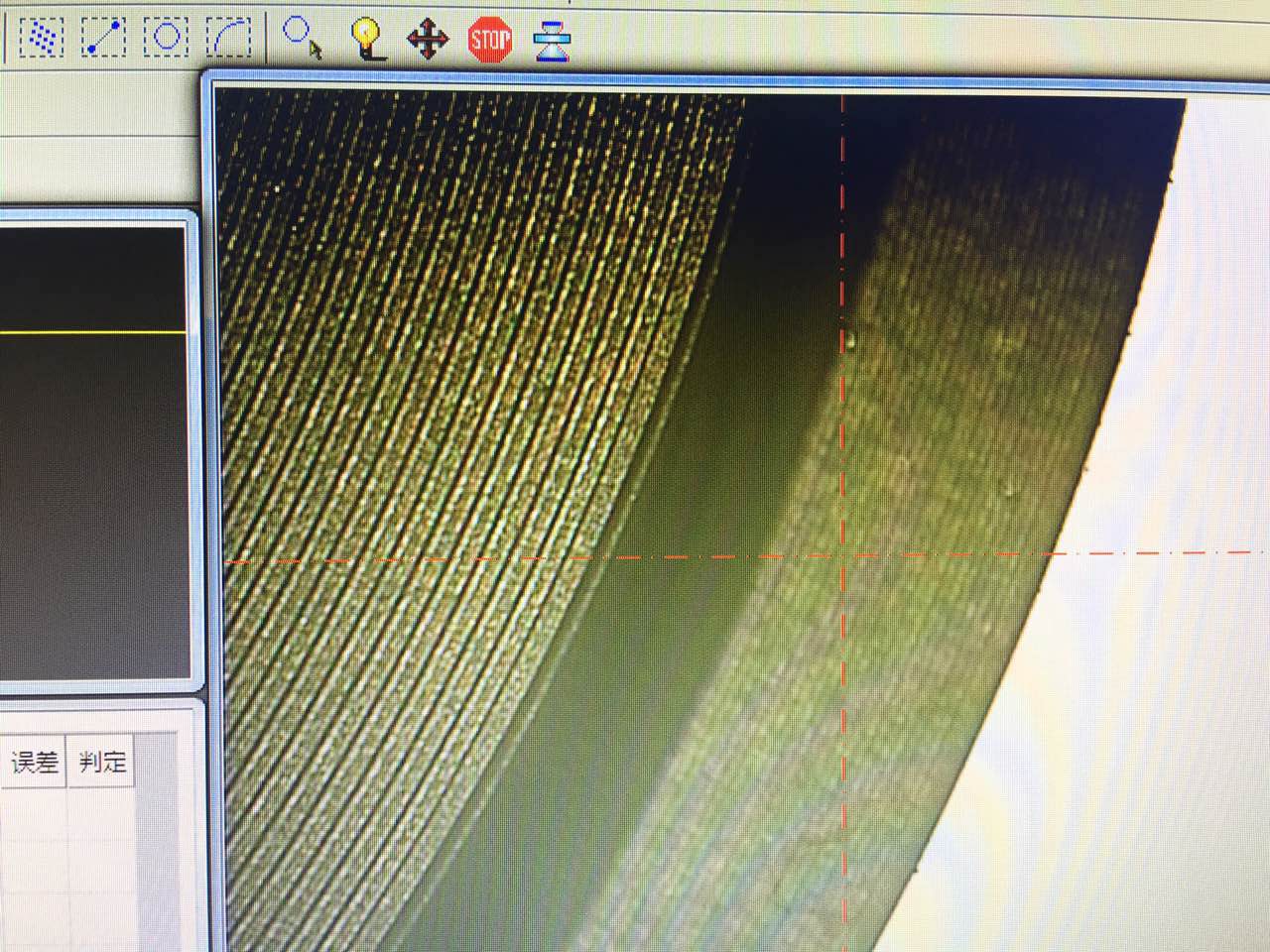

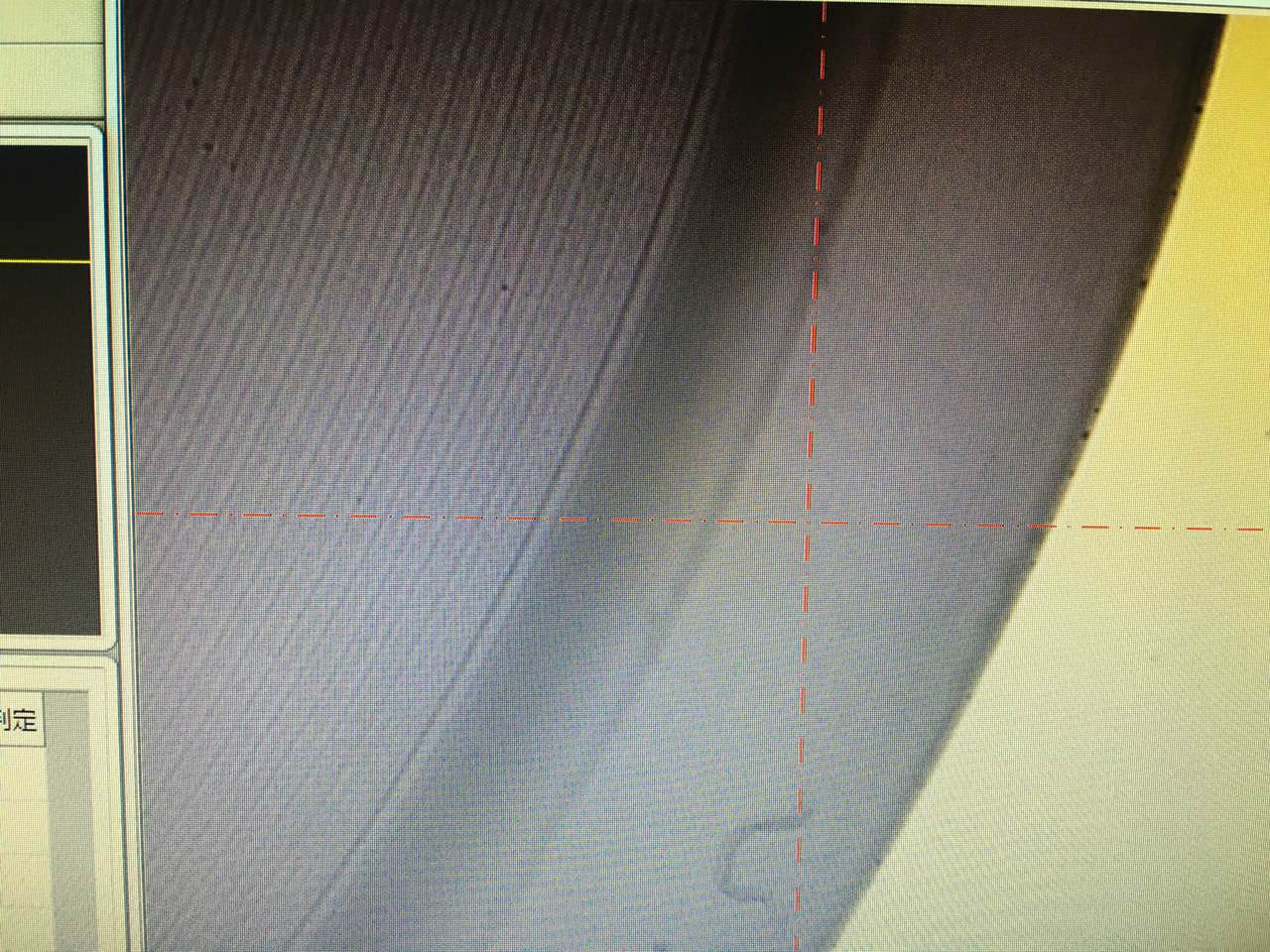

Yixin coaxial optical VS peer non-coaxial optical

Coaxial optical interface Ordinary light

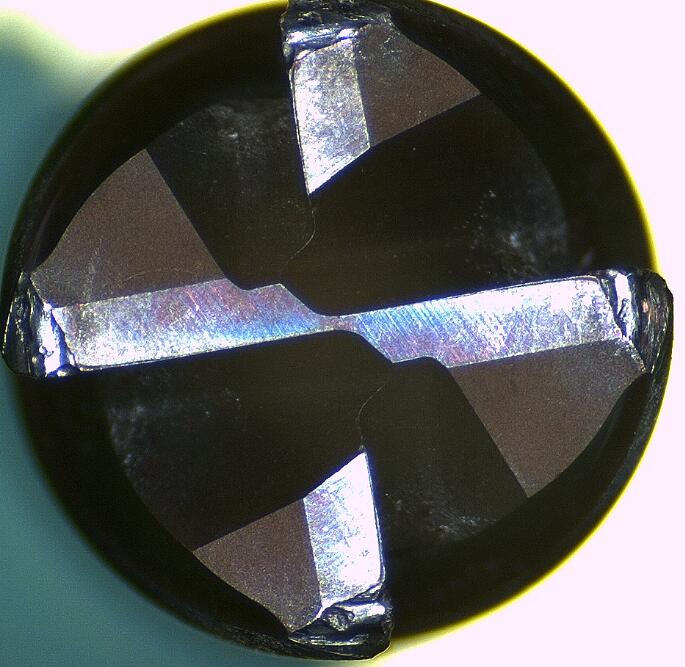

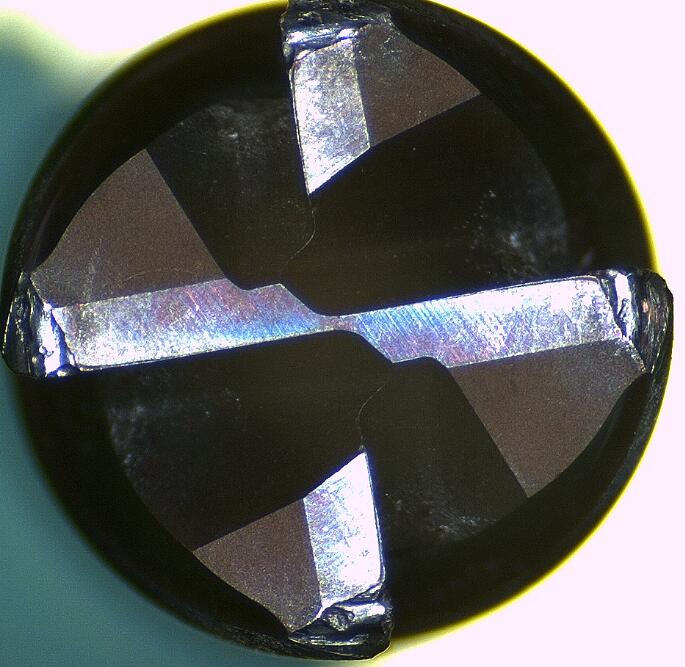

Yixin high-definition camera VS counterpart ordinary camera

High-definition CCD tool picture for Yixin imager Ordinary CCD tool picture

Yixin absolute grating ruler VS counterpart ordinary grating ruler

Yixin 0.01um absolute grating ruler, high precision, high resolution 0.5um ordinary grating ruler

Image measuring instrument installation and acceptance standards

1. Equipment acceptance, inventory and installation adjustment test acceptance

1.1 Acceptance of equipment

The acceptance of equipment is divided into two stages, namely: the first and final acceptance, and the method of acceptance shall be carried out in accordance with the technical agreement reached by both parties.

1.1.1 The first acceptance: After the equipment has passed the factory inspection and acceptance, after the equipment is delivered to the buyer’s project site, the relevant personnel of the buyer and seller jointly open the box and inspect the goods; if there are problems such as shortage of goods, quality, damage, etc., detailed records should be made. The seller will first immediately and unconditionally replace or make up for the buyer, and then check the reason and hold the responsible person accountable. After no doubt, the first acceptance was passed. The seller also provides the test report and product qualification certificate before leaving the factory;

1.1.2 Final acceptance: After the installation and commissioning of equipment and materials are completed and the acceptance criteria are reached, the buyer and seller shall send personnel to jointly check and accept the goods. Upon confirmation by the buyer and the seller, the final acceptance shall be qualified.

2.1 Installation and adjustment test acceptance

The seller is responsible for completing the installation and commissioning of the equipment at the buyer’s site free of charge. For installation at the buyer’s site, the buyer should prepare the gas, electricity, grounding protection and other infrastructure in advance, and notify the seller by fax, and communicate in advance if there is any problem to ensure a smooth installation. The company is responsible for the installation and commissioning of the measuring machine. All packaging boxes can only be opened under the supervision and approval of the engineer. According to needs, users need to provide internal disassembly, transportation and in-place support. The final acceptance will be carried out according to the enterprise standard Q/320505AD005-2012. After the commissioning is completed, the equipment shall be checked and accepted, and the acceptance of the equipment shall be carried out in accordance with the technical agreement reached by the two parties. Various technical indicators shall be implemented in accordance with the contents of the "Technical Agreement" signed by both parties. After the acceptance is completed, both parties shall jointly confirm, and the representatives of both parties shall sign the "Installation and Commissioning Test Acceptance Report".

Packaging and transportation plan of image measuring instrument

Packaging and shipping

- Use good wooden box packaging and road transportation to ensure good equipment. The problem of packaging and transportation shall be borne by the seller.

- After the goods arrive at the buyer, the seller’s personnel will arrive at the buyer’s site within one working day to unpack the goods, install and debug the equipment.

Image measuring instrument installation plan and plan, installation, construction organization and personnel situation

Installation plan

Before installing the instrument, please read this "Precautions for Installation"

Installation Precautions:

- Please place this product in a ventilated and dry place, and try to keep the ambient temperature between 20℃-25℃.

- Do not place this product in dusty and humid places.

- This product uses 220V, 50-60HZ AC power supply. This product requires a good connection and grounding of the power supply.

- Please place this product away from strong electric fields or strong electromagnetic interference sources, such as AC cabinets, large machine tools, electromagnets, electric spark machines, etc.

- To ensure measurement accuracy, please place this product away from vibration sources, such as punches, vibrating machines, etc.

- Do not disassemble or adjust product parts by yourself. Do not use accessories not produced or provided by our company.

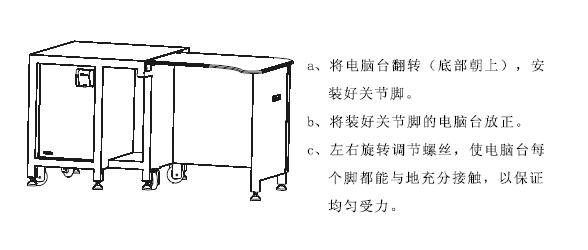

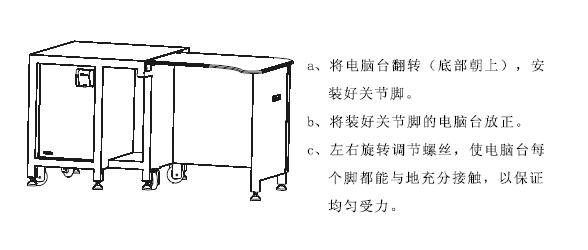

1. Install the computer desk

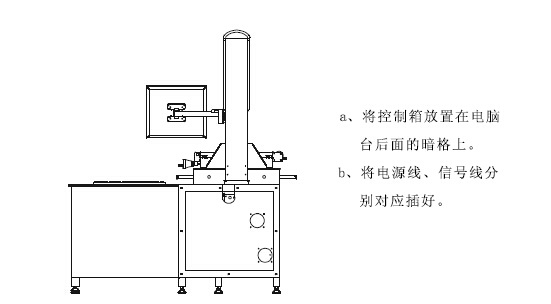

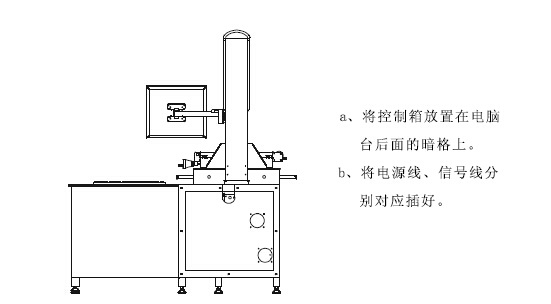

2. Install the electric control box

3. Install the computer

a. Very good connection of all parts of the computer.

b. Insert the video cable from the 2D body into the AV1 port of the computer video interface

Our company is equipped with an excellent team composed of senior CNC engineers and senior account managers, and experienced application engineers provide a complete set of turnkey projects.

0086-574-87488065

0086-574-87488065

Messages

Messages