ATM-4030 Automatic high-precision two-dimensional image measuring instrument

1. Technical parameters

|

Specifications Model: ATM-4030

|

|

Measuring range (mm)

|

Dimensions (mm)

|

Host weight (Kg)

|

Maximum bearing weight (Kg)

|

|

X

|

Y

|

Z

|

L

|

W

|

H

|

|

400

|

300

|

250

|

1600

|

950

|

1900

|

410

|

30

|

|

Maximum space movement speed

|

Maximum spatial acceleration

|

|

465mm/s

|

870mm/s

|

|

measurement accuracy

|

|

Optical one-dimensional length measurement error: EU X/Y(1D)(μm)

|

2.0+L/200 MPE complies with JJF 1318-2011

|

|

Optical two-dimensional length measurement error: EU XY(2D)(μm)

|

2.0+L/200 MPE complies with JJF 1318-2011

|

|

Two-dimensional detection error: PF2D(μm)

|

2.0 MPE complies with JJF 1318-2011

|

|

Image probe detection error: PFV2D(μm)

|

2.0 MPE complies with JJF 1318-2011

|

|

Serial number

|

Name

|

Specification and description

|

|

1

|

Host and machine

|

The main body of the fuselage is made of high-precision natural granite, which has stable temperature characteristics and resistance to aging deformation.

|

|

2

|

Control System

|

The AR3 network board, network interface main board, servo motor and drive have been upgraded in all aspects. The Z-axis has a brake system to ensure the stability and safety of the machine and more accurate positioning.

|

|

3

|

Easson measurement software system

|

Automatic version of optical vision measurement software

|

|

4

|

camera

|

1.3 million digital high-definition web camera

|

|

5

|

Grating ruler

|

0.01μm absolute grating

|

|

6

|

Guide

|

The three axes adopt precision ball screw guides, the speed is greatly improved, and the operation is stable

|

|

7

|

Motor

|

DC servo motor

|

|

8

|

Lens

|

Easson independently designed TC precision multi-segment fixed magnification automatic zoom telecentric lens (standard coaxial light) actual magnification: 30-145×

|

|

9

|

Lighting system

|

5 rings and 8 zones LED cold light source is independently controlled for each segment, 256 levels of brightness adjustable

|

|

10

|

Brand Computer

|

WIN7/WIN10

|

|

23.8 HD

|

|

11

|

Operation method

|

Remote control handle, mouse consignment, program detection

|

2. Environmental conditions and requirements

|

The temperature requirements of the imager room:

|

|

Room temperature (temperature control room)

|

18~22°C

|

|

Temperature gradient (time)

|

1°C /h

|

|

Temperature gradient (time)

|

2°C /24h

|

|

Temperature gradient (space)

|

1°C /m

|

|

Humidity requirements for imaging room:

|

|

relative humidity

|

40-70%

|

|

Power requirements:

|

|

Voltage

|

220V ± 10%

|

|

frequency

|

50/60 Hz

|

|

shock

|

Below 15Hz<0.001g

|

|

power consumption

|

1000VA

|

|

Electrical equipment requires reliable grounding: the grounding resistance is less than 4 ohms

|

3. Software features

(a) Basic functions:

●Cartesian coordinate/polar coordinate conversion ●Absolute/relative/working coordinate conversion

●Metric/English conversion ●Degree/degree, minute, second conversion

●Point/Point Group ●Two-point/multi-point seeking line

●Three-point/multi-point finding circle and arc ●Bspline

●The distance between two points ●The average distance between two lines

●The distance between dots and lines ●The distance between two circles

●Circular line distance ●The angle and intersection between two lines

(b) special function

1. Full computer program to control the light source. The upper light source is a four-phase lamp, and the lower light source is a straight light source, which increases the adaptability of the machine; and has a luminosity indicator function to guide users and reduce uncertain factors caused by humans.

2. There is no need to adjust the position for measuring the workpiece, and the software provides coordinate translation, rotation, and position.

3. The annotation function allows the user to mark/move the size directly in the image and geometric area.

4. Geometry zone points, lines, circles/arcs and straight line endpoints, midpoints, circle centers, quadrant points are automatically captured.

5. CCD parameter settings can be adjusted to improve self-adaptive force; the function of removing burrs to obtain the measurement data correctly.

6. Use the image tool to quickly and automatically grab the boundary points of the basic geometric contours, and directly fit the lines, circles, and arcs.

7. The workpiece in the measurement area is zoomed in and outputted by the camera and converted into (.bmp, .jpg).

8. The measurement data is output and converted into WORD (.doc), EXCEL (.xls).

9. Easy-to-operate self-learning teaching programming software, the program can be executed repeatedly

10. SPC function, directly output the control chart and convert it to EXCEL

11. Direct output of mechanical graphics in .dxf format, seamlessly connected with AutoCAD, Pro/e and other software.

12. The program can directly input .DXF files, and realize the intuitive measurement comparison between the actual enlarged image of the workpiece and the standard design drawing in the image measurement area.

13. Provide in-plane straightness, roundness, and angle analysis for effective quality inspection

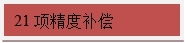

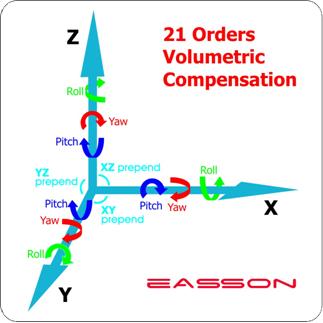

14. The accuracy of the machine is compensated to improve the measurement accuracy.

15. The software of the ATM-4030T automatic image measuring instrument has a learning function. The user only needs to manually measure the workpiece once, and the entire measurement process will be recorded for subsequent repeated automatic measurements. The user does not need to write any programs, and the operation process is absolutely simple and easy.

16. Re-measurement function: This function can re-change the measurement method, lighting, magnification, etc., for the elements that have been measured, and then refresh the measurement data, and the related element data will also be refreshed (such as: two-line construction distance, if If one of the lines is re-measured, the distance element data will also be refreshed).

17. Modify, edit and view the edge-seeking status: the software can modify and edit the edge-seeking range, light source brightness, magnification, etc. of any measurement element. You can also view the edge-finding status of a certain element measured before (including the position of the edge-finding, the brightness of the light source used, the magnification and the original point taken, etc.), so that the user can control the status of the whole process of measurement.

Four. feature description

The scientificity and rationality of the machine design, the selection of materials, and the level of manufacturing technology

As the measurement accuracy is required to be as high as (1.9+L/150), the measurement data uses the fastest and most reliable LAN interface to connect to the computer. The connection between the LAN and the commonly used USB has the following obvious technical advantages: (1) Anti-interference The performance is more reliable and stable than USB, and can be transmitted over long distances; (2) LAN speed is faster than USB. The company’s dedicated controller has simple hardware structure, few wiring and neat, convenient arrangement and maintenance. The fuselage platform and Z axis are made of high-quality 00 granite, and the straightness of all guide rails and moving parts has passed the collimator. The measurement is confirmed to meet the straightness standard of our company.

At present, all the ATM series of automatic machines have to perform 2000 "burning measurements" before leaving the factory. We use a glass ruler to move the table in the four directions, X, 45 degrees, Y, and 135 degrees. The direction was repeated 500 times, a total of 2000 times, measuring a length of 180 mm, we will record all the measured data, the maximum and minimum size difference must be guaranteed to be within 2um before leaving the factory!

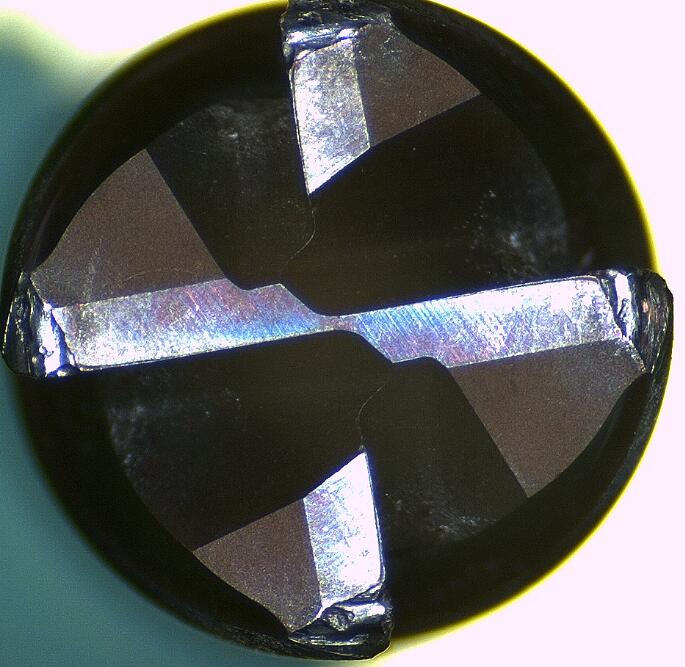

F1 High-precision, fully closed-loop, automatic zoom telecentric lens The features are as follows:

Adopt the high-precision, high-resolution ring-type grating ruler specially developed and designed by our company for F-1 for full closed-loop position feedback

High resolution, fully closed loop position feedback, avoiding the repetition error of image multiples caused by gear transmission gap, greatly improving the repeatability of the whole machine measurement.

The resolution of the ring grating is 20 times higher than that of the previous generation zoom lens.

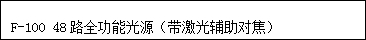

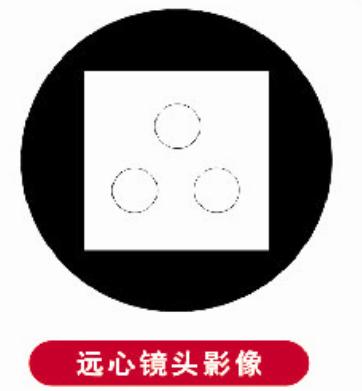

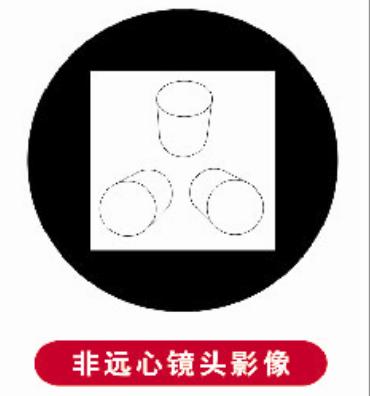

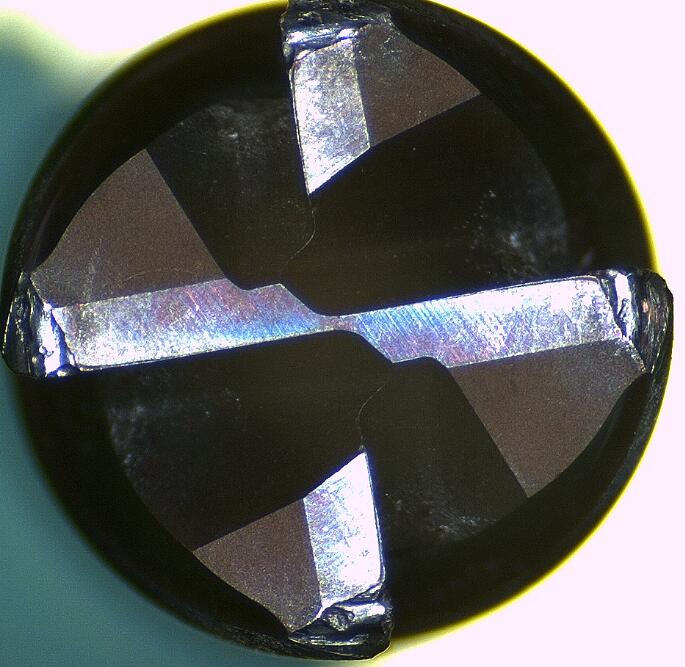

Yixin telecentric lens VS non-telecentric lens

The use of non-telecentric lenses for imaging will produce perspective artifacts and bring test errors.

Use a telecentric lens to correct the image of the light source without distortion and improve the measurement accuracy.

Yixin coaxial optical VS peer non-coaxial optical

Coaxial optical interface Ordinary light

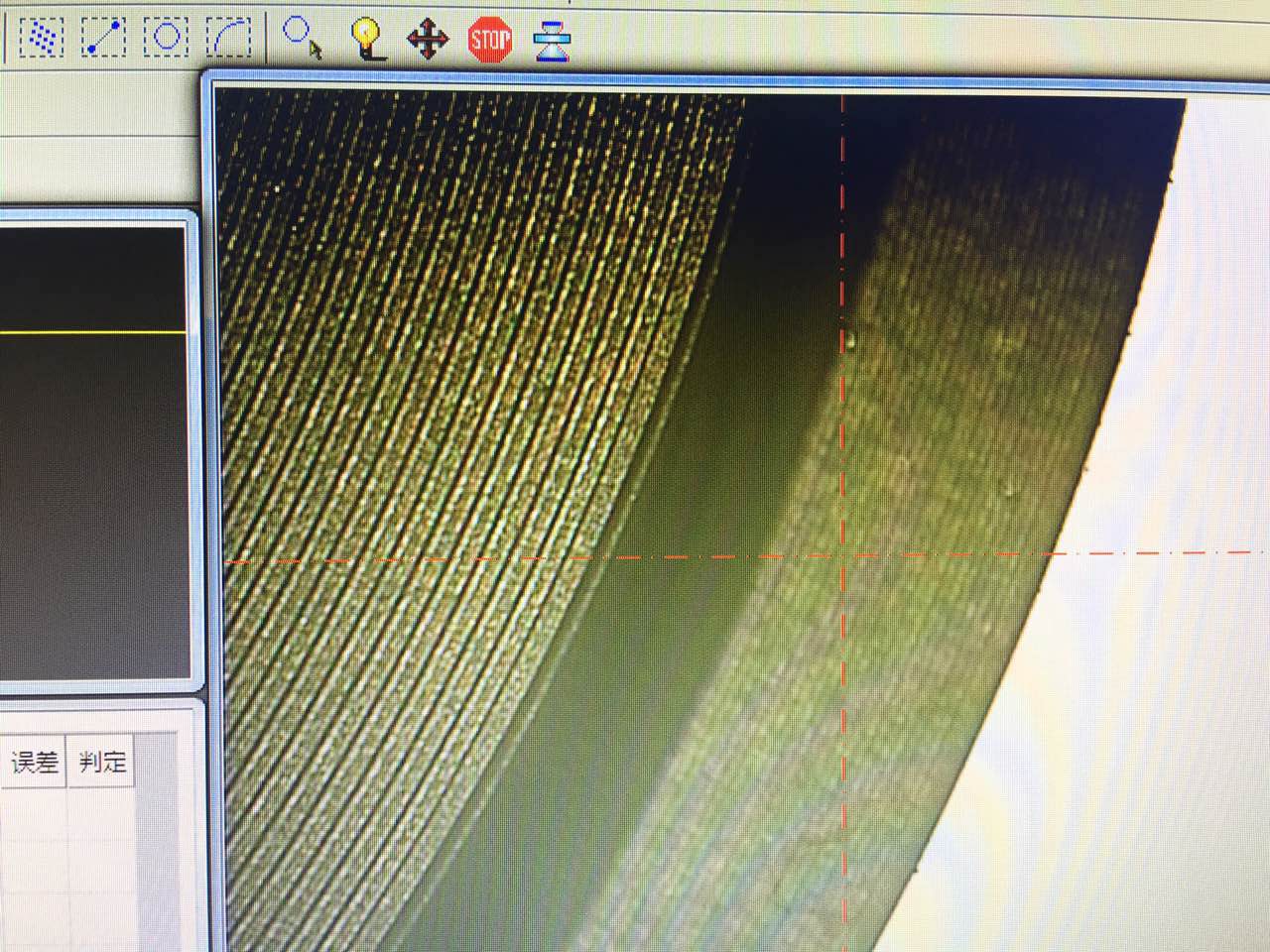

Yixin high-definition camera VS counterpart ordinary camera

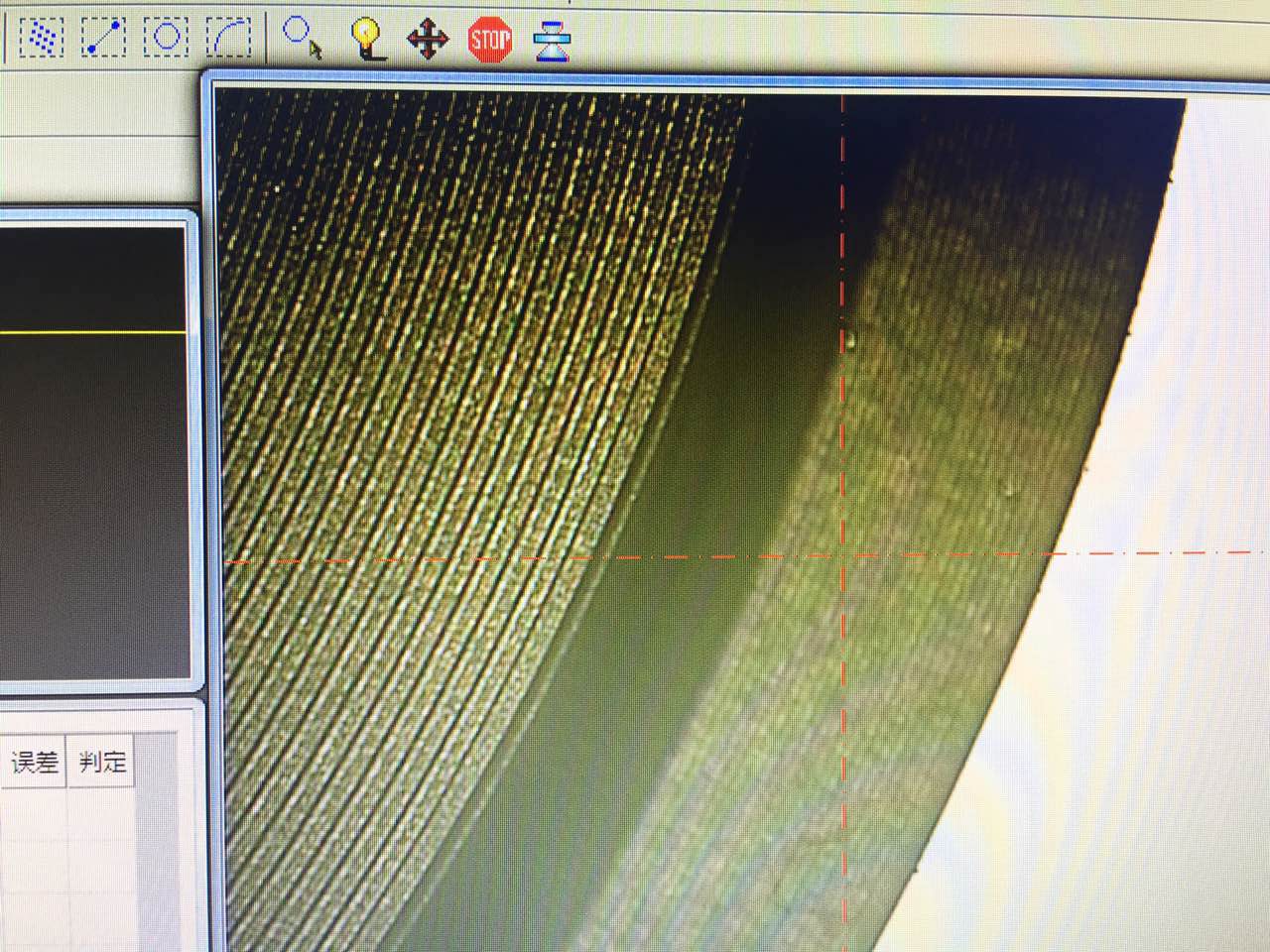

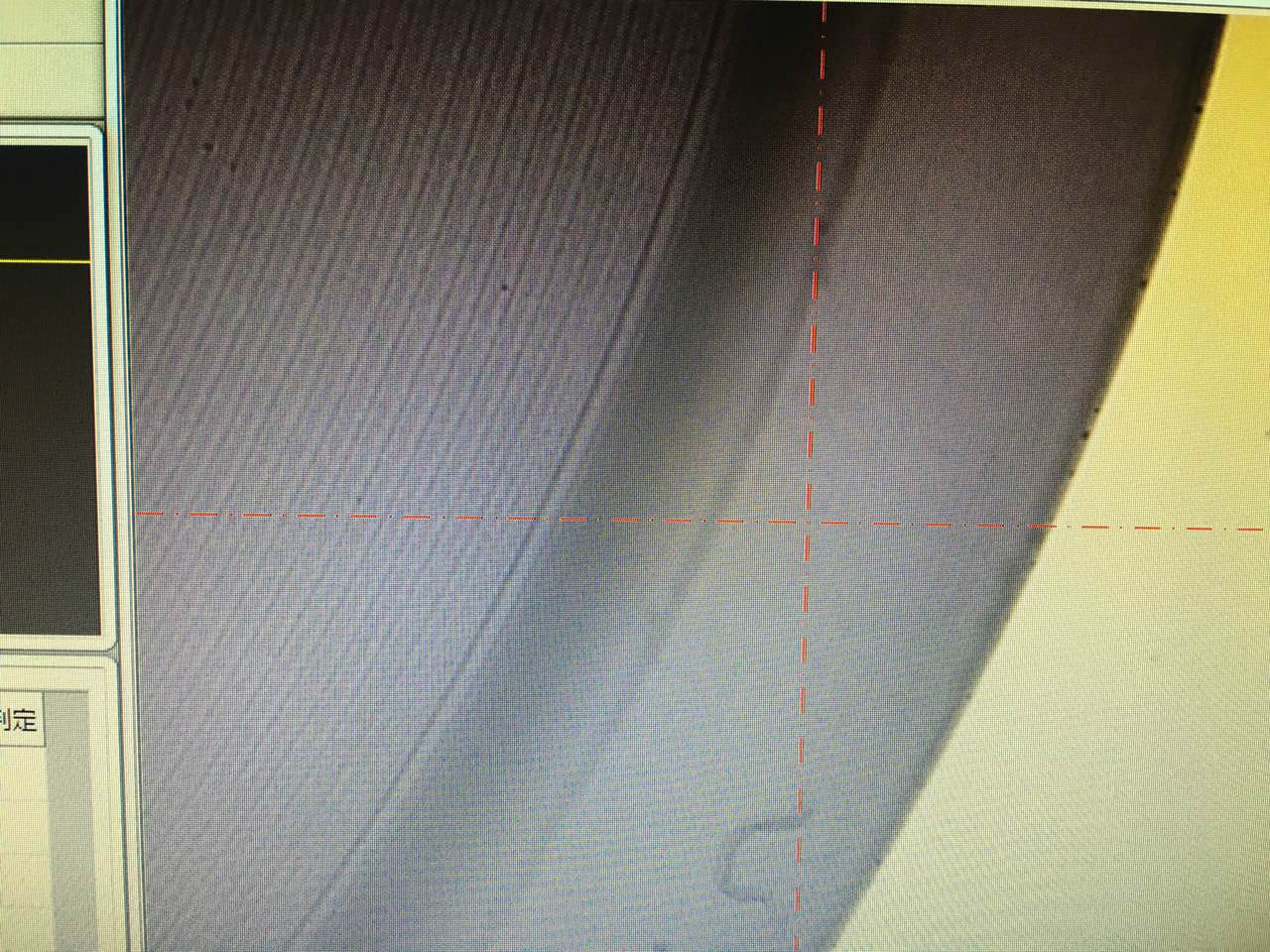

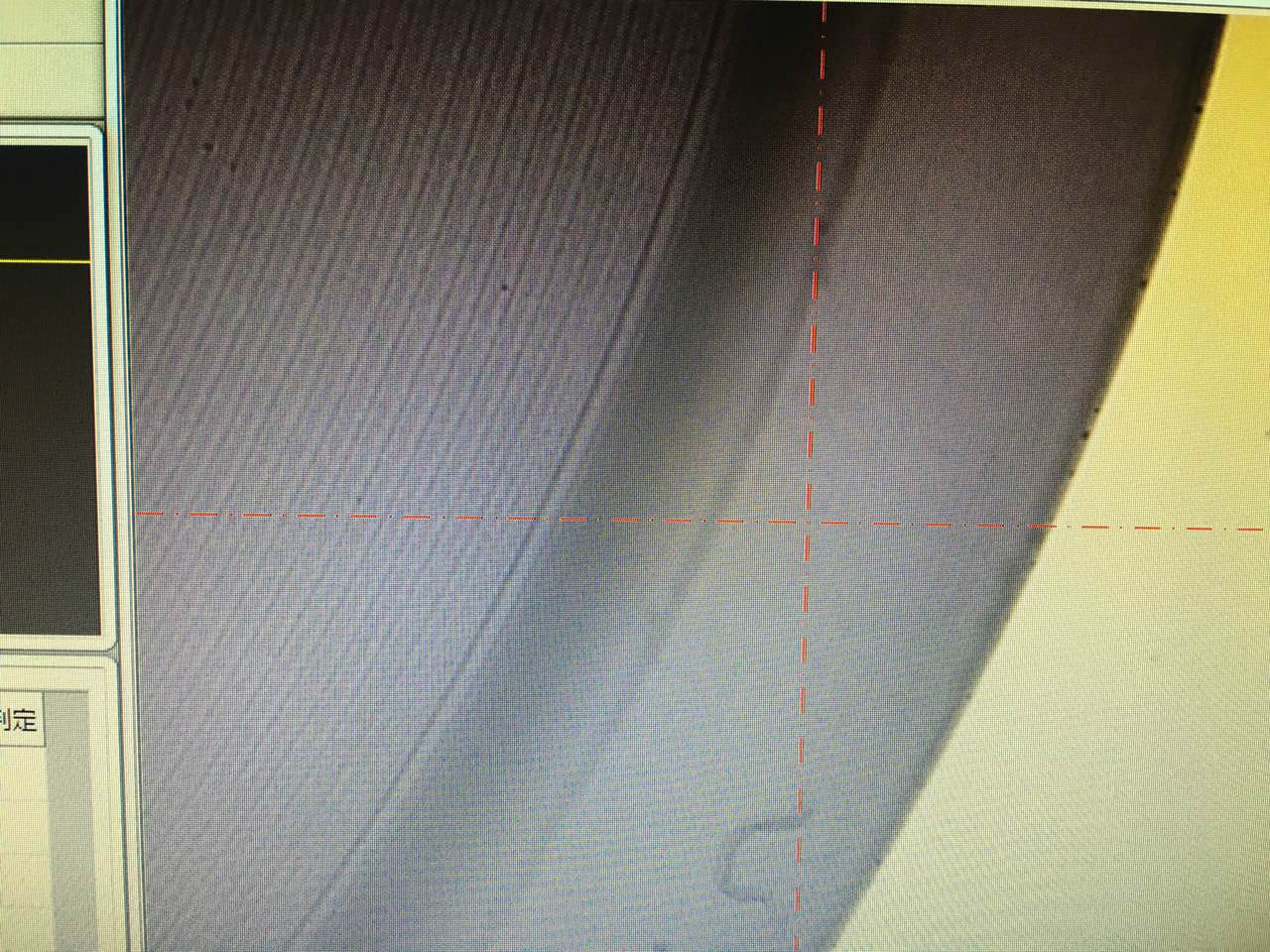

High-definition CCD tool picture for Yixin imager Ordinary CCD tool picture

Yixin absolute grating ruler VS counterpart ordinary grating ruler

Yixin 0.01um absolute grating ruler, high precision, high resolution 0.5um ordinary grating ruler

Five, transportation, installation, after-sales

Packaging and shipping

- Use good wooden box packaging and road transportation to ensure good equipment. The problem of packaging and transportation shall be borne by the seller.

- After the goods arrive at the buyer, the seller’s personnel will arrive at the buyer’s site within one working day to unpack the goods, install and debug the equipment.

Installation plan

Before installing the instrument, please read this "Installation Precautions"

Installation Precautions:

- Please place this product in a ventilated and dry place, and try to keep the ambient temperature between 20℃-25℃.

- Do not place this product in dusty and humid places.

- This product uses 220V, 50-60HZ AC power supply. This product requires a good connection and grounding of the power supply.

- Please place this product away from strong electric fields or strong electromagnetic interference sources, such as AC cabinets, large machine tools, electromagnets, electric spark machines, etc.

- To ensure measurement accuracy, please place this product away from vibration sources, such as punches, vibrators, etc.

- Do not disassemble or adjust product parts by yourself. Do not use accessories not produced or provided by our company.

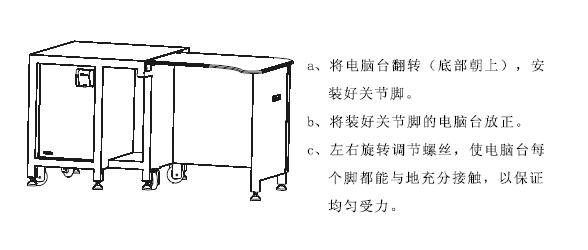

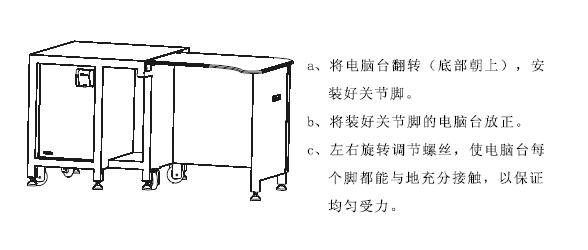

1. Install a computer desk

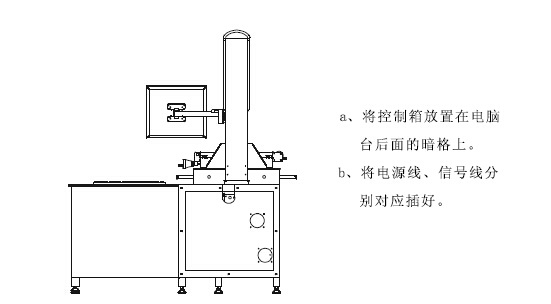

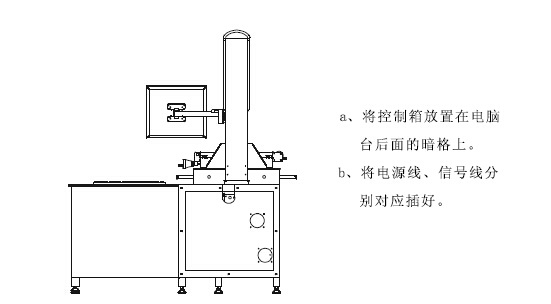

2. Install the electric control box

3. Install the computer

a. Very good connection of all parts of the computer.

b. Insert the video cable from the 2D body into the AV1 port of the computer video interface

Our company is equipped with an excellent team composed of senior CNC engineers and senior account managers, and experienced application engineers provide a complete set of turnkey projects.

Training program and after-sales service

Build the foundation with quality, use talents as the driving force, seek development with innovation, build reputation with service, and win customers with integrity. Ningbo Yixin Optoelectronics Technology Co., Ltd. is committed to the innovation of key technology of measuring instruments, sincerely cooperate with customers, learn from each other, and form a cohesive excellent team to serve customers well.

1. After the instrument arrives at the user's location, the user prepares the electricity and other conditions required for the normal operation of the instrument, and the professional engineer opens a new box to check the instrument.

2. After the engineer passes the inspection on the use site of the instrument, install, debug, and compensate for the accuracy, and then test the accuracy again after installation.

3. The training equipment has the same model and function as the instrument purchased by the user. Responsible for comprehensive training on the basic principles, use, operation, maintenance, etc. of the product.

4. Training operation standards, operation "should know" and "should know".

5. Training content: switch machine operation, job preparation, instrument calibration, measurement steps, precautions, common problem handling procedures.

6. Instrument maintenance training: maintenance component name, maintenance content explanation, maintenance cycle, maintenance methods and standards, and maintenance personnel's responsibility post requirements.

7. Each instrument is accompanied by technical data such as manuals, cargo certificates, packing lists, etc.;

8. There are detailed inspection records during the equipment installation and commissioning process, and the commissioning and inspection results meet the relevant national standards. And fill in the acceptance report and report it to the user manufacturer.

9. The warranty period is no more than thirteen months from the date of delivery, and is responsible for lifelong maintenance of the equipment. During the warranty period, maintenance fees are waived, and spare parts that are not damaged by humans will be replaced free of charge.

10. After receiving the repair report from the user, immediately call to communicate and guide the solution. If the phone cannot be solved, a solution will be given within two hours, and the problem will be solved at the customer site within 24 hours. (Except national holidays)

11. Provide free software upgrade service within three years.

0086-574-87488065

0086-574-87488065

Messages

Messages